Production Overview

芯片采購網專注整合國內外授權IC代理商的現貨資源,實時查詢芯片庫存,合理行業價格,輕松采購IC芯片,是國內專業的芯片采購平臺。

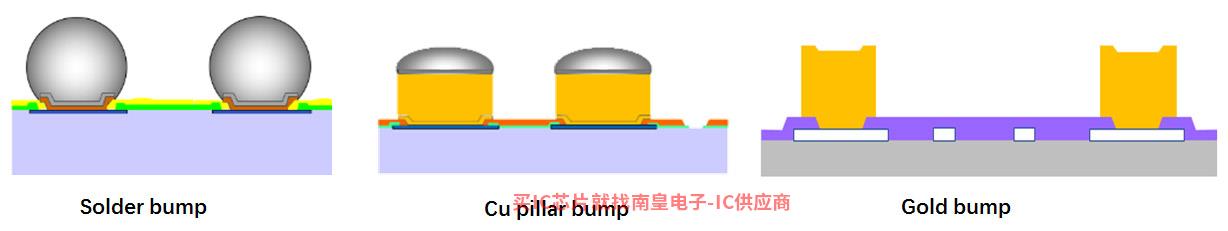

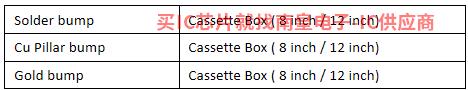

TFME is able to provide Solder bump, Cu pillar bump and Gold bump for customer to meet different requirement.

Solder bump Cu pillar bump Gold bump

- Wafer size: 8 inch / 12 inch - Wafer size: 8 inch / 12 inch - Wafer size: 8 inch / 12 inch

- Structure: 0P1M~2P2M - Structure: 0P1M~1P2M -Structure: 0P1M~1P1M

- Body size: 0.7*0.76~10.7*10.7 mm - Body size: 1.0*1.5~10*10mm - Structure: 0P1M~1P1M

- RDL L/S: min.5um/5um - RDL L/S: min. 5um/5um - Bump L/S: min.10um/8um

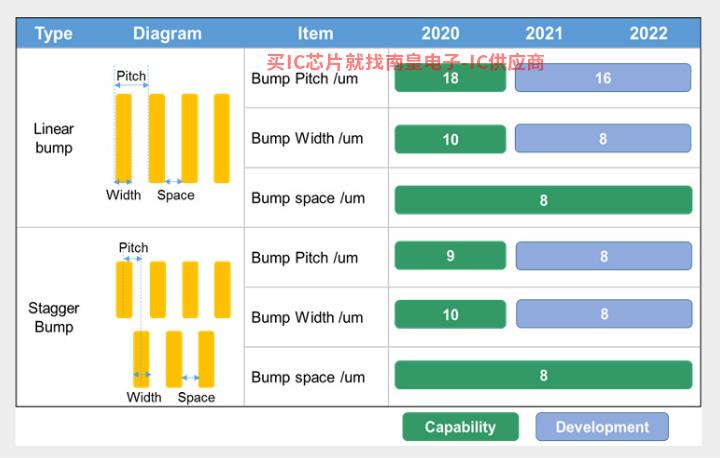

Solder bump & Cu pillar

Process Capability & Design Rule

Gold bump

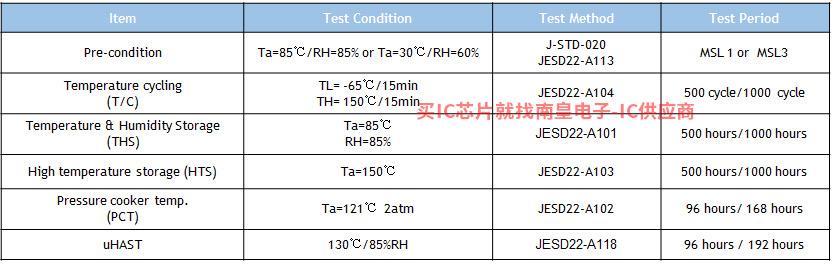

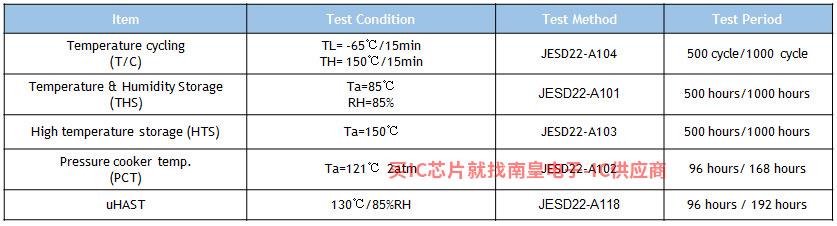

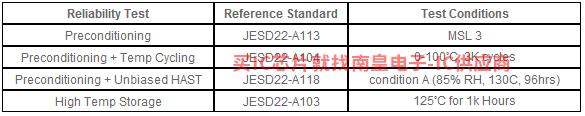

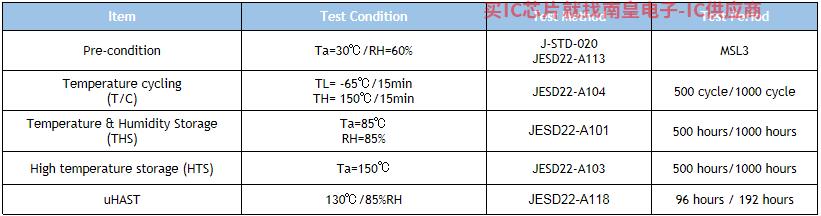

Reliability Test Standards

Solder bump & Cu Pillar bump

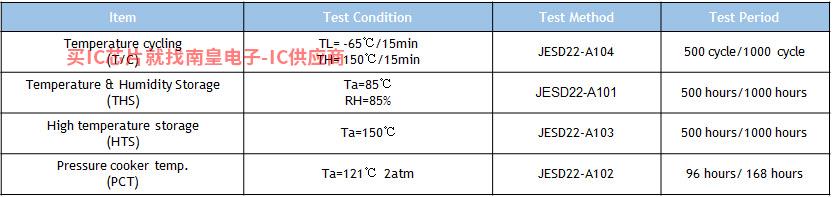

Gold bump

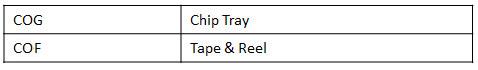

Shipment Packing

Production Overview

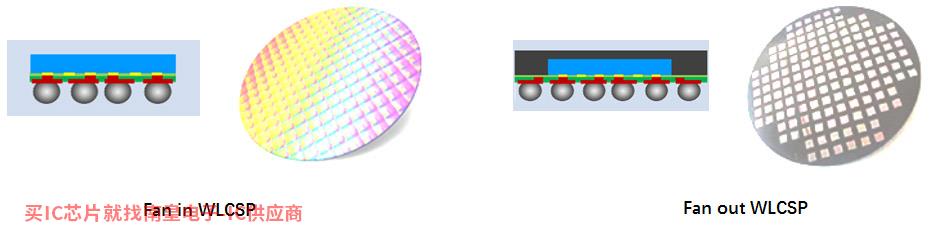

TFME offers various Wafer Level CSP product to customer including Fan in type and Fan out type.

Feature

Fan in WLCSP Fan out WLCSP

- Ball count : 2~309 - Ball count : 36 ~203

- Structure: 1P1M~2P2M - Structure: 1P1M~3P3M

- Body size: 0.6*0.3~7.6*7.6mm - Body size: max 20*20mm

- RDL L/S: min.5um/5um - RDL L/S: min.2um/2um

Process Capability & Design Rule

Fan in WLCSP

Process Capability & Design Rule

Fan out WLCSP

Reliability Test Standards

Shipment Packing

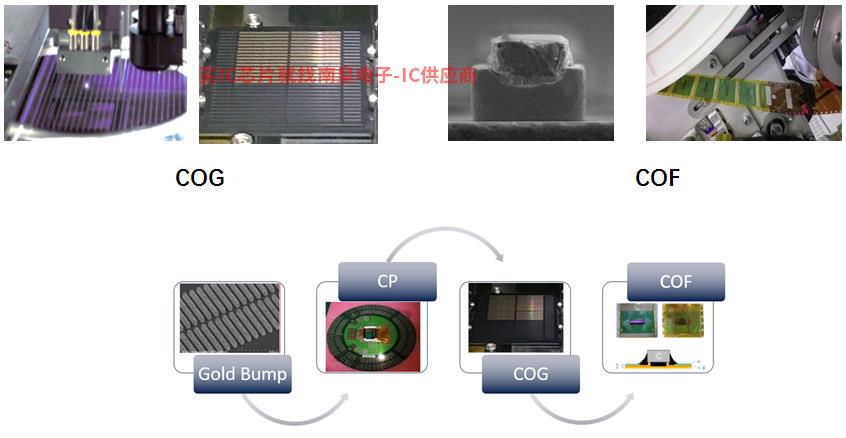

Production Overview

TFME is able to provide COG (Chip On Glass) and COF (Chip On Film) services for gold bump drive ICbased on customer requirement.

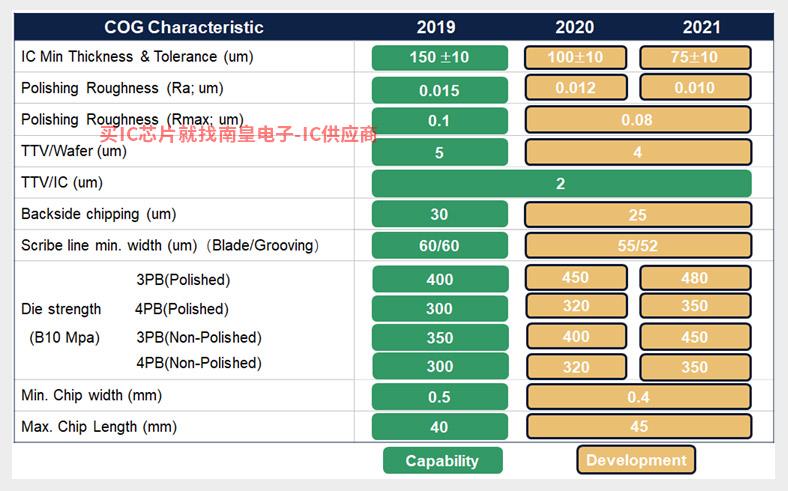

Process Capability & Design Rule

COG

Process Capability & Design Rule

COF

Reliability Test Standards

Shipment Packing

Production Overview

Flip Chip interconnection, also knownas Controlled Collapse Chip Connection, C4, has been identified as a high performance packaging solution to meet the growing need for products with increased electrical performance, high I/O, and high system reliability as a replacement for conventional wire bond process. Utilizing whole die area as for electrical connection, substrate I/O per unit exponentially increased vs. perimeter wire interconnection technology.

Flip chip interconnect also allows direct connection with on-die power planes which enables increased electrical performance including increased switching speed and more efficient power distribution to the IC performance at lower operating voltages.

TF-AMD Flip Chip are assembled with single unit laminate which is the highest routing density through build-up technology to maximize the device performance &conventional ceramic substrate for reliability enhanced package solution. Combined with Flip Chip interconnection, TF-AMD provides optimal design flexibility for final package design& product format to fit an end user requirement.TF-AMD offers Flip Chip BGA packages with ball counts up to 3000 & PGA package up to 2000

Application

Flip Chippackage is considered one of the most established industry platform applicable for high pincount and/or high performance ASICs. Large body FC BGA/PGAs provide package solution forComputing (microprocessors / graphic, server), gaming,high bandwidth networking/Communicationdevices. Combined with Flip Chip technology &BGA/PGAlead format, TF-AMD help to enable SMT and also pin insertion application.

Features

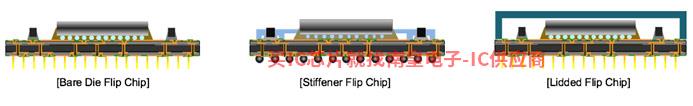

Flip Chip BGA/PGA Packaging

Package Types: Bare die, Stiffener, Lidded (Top hat & flat top)

Wafer Node 314/16nm ELK(extreme low K) qualified, 7nm in development.

Package sizes from 12mm to 55mm (75mm in development)

Die area up to 800mm^2

Lead Free, Eutectic, High-Pb bump for Flip Chip connection

Passive component size down to 01005

High thermal performance solution using Indium metal TIM

Substrate

o 4 – 18 layers laminate build up

o Coreless, 0.2mm, 0.4mm, 0.8mm, 1.0mm available

o High CTE ceramic / LTCC alumina ceramic

o BGA / PGA

Footprints Pitch

o BGA : 0.5mm, 0.65mm, 0.8mm and 1.0mm

o PGA : 1.0mm, 1.27mm

Other Option

o Multi-die capability

o Die binning to waffle pack up to 256 BINs

Flip Chip BGA/PGA Test

Test Product Engineering

o TF-AMD test provides a competitive test solution to our customers ranging from test development, platform conversion, and product maintenance and test data analysis.

o The team has rich test development experience of various product portfolio, including high-end digital, mix-signal, SOC and high speed products.

Adding Value to Customer

o Reduce customer overhead by outsourcing projects / tasks to avoid maintaining a large scale of dedicated team

o Incorporate industrial standard through leveraging best known method from our database & continuous cost saving by driving test time reduction, yield improvement

Service Solutions

o Wafer Sort test development

o Final Test development

o Low cost platform conversion

o Multi-site enablement

o Burn-in capabilities

Test Development Experience

o CPU, APU, GPU

JST代理 o Chipset

o Digital Audio

o Baseband

o Microcontroller

o LCD Driver

o Touch Panel Driver

ATE platforms and products

Reliability Test Standards

Design Rule

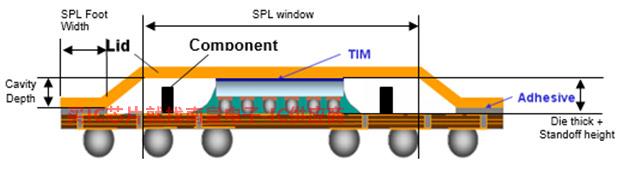

Top Hat Single Piece Lid

Lid size=substrate size-0.2mm

Standard foot sizes

o 2mm for 15-25mm body

o 3mm for 27-31mm body

o 4mm for 33-50mm body

Max 3mm on all four sides (UF will flow under the bend/slant of the HS). Extended design rule allow Max. 2.5mm for the body size ≤31mm

Lid is centered

Cavity depth for 12inch wafer SPL is 0.8mm and total thickness is 1.3mm

o TIM Thickness target: 40um (Max. 100um)

o Adhesive Thickness target: 120um (Max. 200um)

o Lid manufacturing tolerance: +/-50um

Body size<31mm support bare die structure (without stiffener/lid construction)

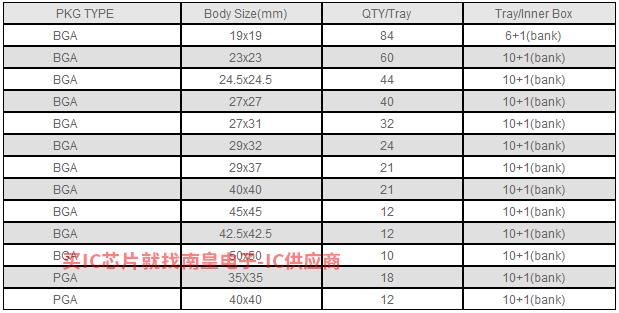

Packing & Shipping (in house standard)

BGA / PGA (Tray)

Production Overview

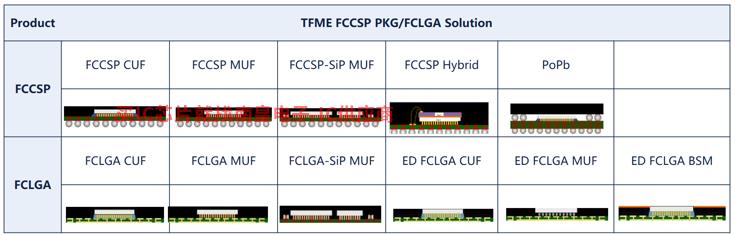

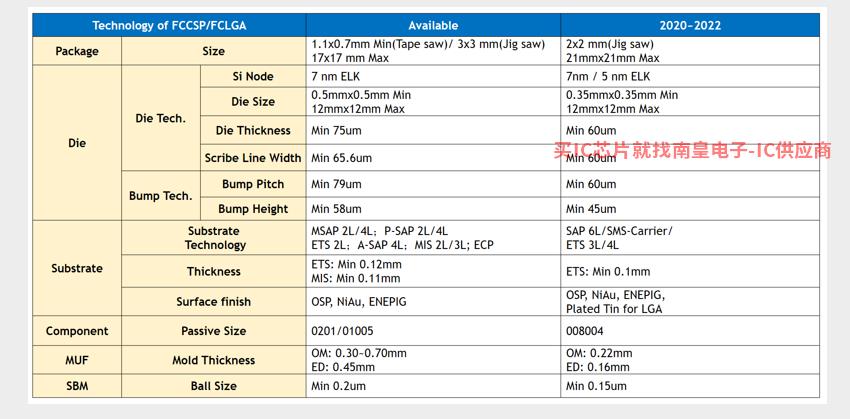

TFME offers various FCCSP and FCLGA package based on customer different requirement.

Features

- SiP (FC + SMT + Wire bond) available.

- CUF, MUF available.

- 7N/12N/14N/16N wafer node mass production

- Various substrate technology qualified including SAP, MSAP, ETS, MIS and SLP.

- Fully Turnkey for wafer bumping, probing, assembly, FT available.

ProcessCapability & Design Rule

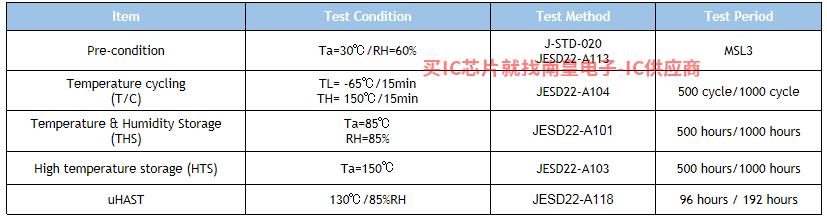

Reliability Test Standards

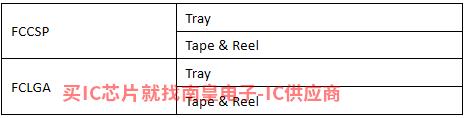

Shipment Packing

Production Overview

TFME offers various WBBGA and WBLGA package based on customer different requirement.

Features

- 1.1x0.7 mm to 21x21 mm Package

- 0.2mm to 1.0mm C Mold Chase

- 01005 Components SMT

- 0.3x0.3 mm Small Die

- 1-6 Layer Substrate

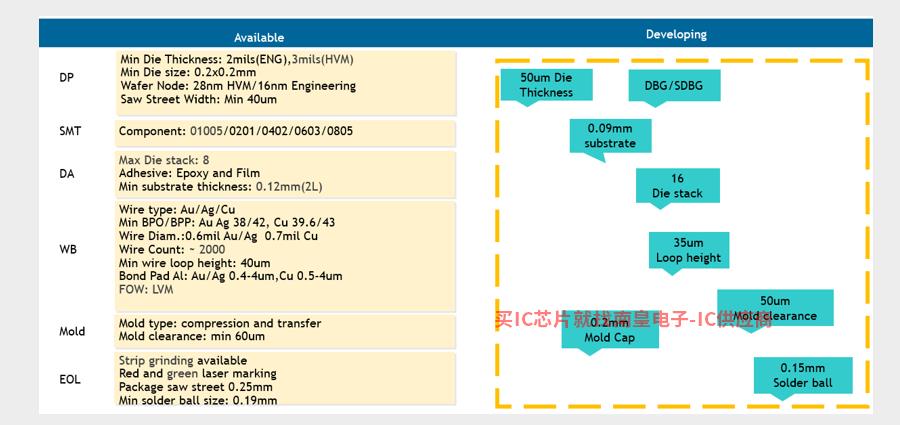

Process Capability & Design Rule

Reliability Test Standards

Shipment Packing

- SpaceX尋求超過17億美元的融資 估值增加到1270億美元

- e銷售東芝最新的智能柵極驅動器

- RISC-V領導者賽芳科技中國IC獨角獸稱號

- 沙特阿拉伯計劃到達 2026 年出口超 15 萬輛電動汽車

- AI智能芯片,拍得更好,拍得更好! 索尼雙影像畫質旗艦Alpha 7R V發布

- 英特爾承諾2040年 每年實現溫室氣體凈零排放

- IAR Systems 全面支持 Renesas RH850有助于汽車行業的創新

- AVEVA劍維軟件獲得兩項智能制造獎項

- 終于等毫米波了!聯發科1050 5G處理器發布

- 兩個重量級人物加入,這個獨立FPGA科技公司要迅速做大

- LG 新能源將為福特提供更多的汽車電池,趕上寧德時代

- 到2030年,所有工廠的75%電力將來自可再生能源